Ideal for small, complex, or irregular shapes.

When to Choose Pad Printing

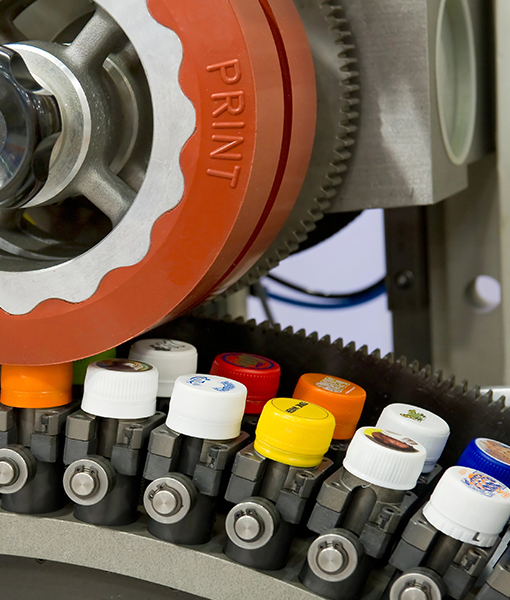

Denmac Industries recommends pad printing for products with irregular shapes and surfaces, such as round, convex, or concave items. This process is particularly efficient for part marking on small products, offering a cost-effective solution for large volume runs. Examples of products well-suited to pad printing include:

With the ability to pad print up to a 4-inch diameter and accommodate multi-color images, Denmac Industries provides a high-quality marking solution to meet your specific needs.

Delivering precision and quality with every print.

Pad Printing Expertise That You Can Rely On

At Denmac Industries, our team of experts works closely with you to determine the best pad printing process for your products, ensuring optimal quality and cost efficiency.

From pre-treatment to packaging, we handle every aspect of the process, providing a seamless experience from start to finish. Connect with us today to get started on your next project!